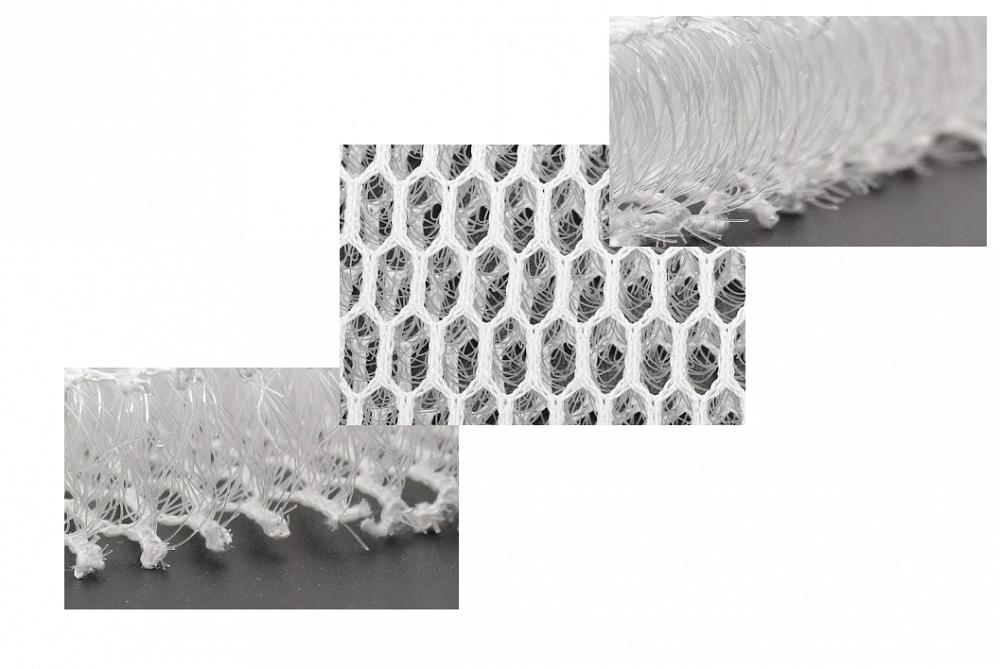

Spacer Fabric 3D

The development and production of smart textiles is the core business of BVS* Tissue Technology from Bielefeld.

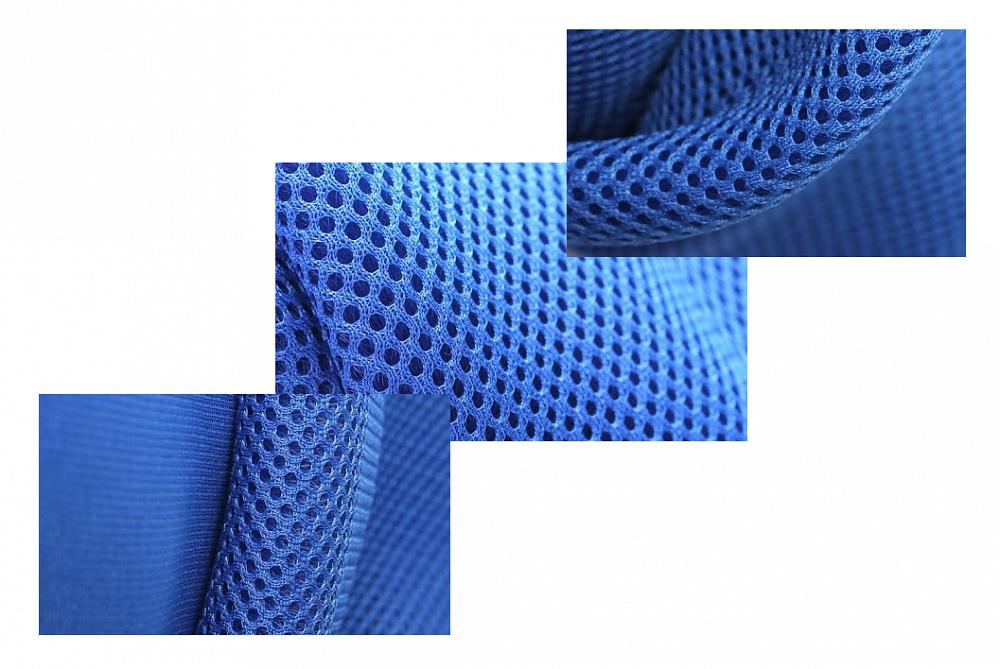

We are hereby active in almost all areas in which, among other things, 3D textiles – spacer fabrics, spacer fabrics, mesh fabrics, perforated fabrics – play a role.

The most important properties of the spacer fabrics are: possible moisture wicking function, good pressure relief, thermoregulation, breathability, good air permeability and other special functions that can be controlled via the specific use of material. These include bioactive effect, flame retardancy, warning protection according to EN471 and also a defined elastic behavior in the longitudinal and transverse directions.

T he areas of application of the high-distance structures are in the areas of clothing, medicine and the automotive sector.

Spacer fabrics are also used in technical applications, such as in industry. Mention should be made here of geotextiles, in sports, in the advertising industry, in the shoe industry, but also in the manufacturers of protective equipment. There is therefore no taboo for 3D spacer fabric.

Owing to the diverse requirements, 3D textiles are mostly manufactured on a customer-specific basis.

The production quantities vary depending on the production weight and the possible application. Mainly synthetic base materials made of polyester, polyamide/nylon are used.

https://www.high-endrolex.com/48

Your templates are taken into account in the production as well as a conceptual production according to your customer requirement profile. We therefore look forward to your inquiries.